Fireproof smoothing is used to achieve a smooth and even finish on surfaces exposed to high temperatures of up to 650ºC. It is useful to know how to lay the smoothie for a satisfactory end result.

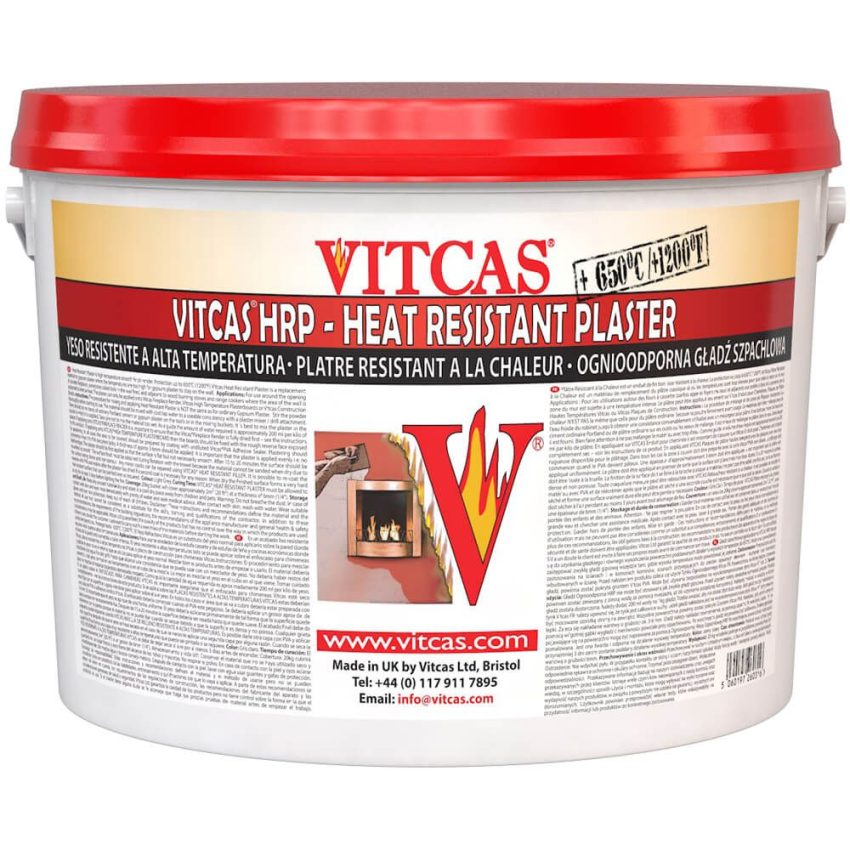

Vitcas HRP smoothing compound, can successfully replace ordinary gypsum smoothing compound in areas where high temperatures cause cracking of the surfaces exposed to it. How to apply the smoothness so that it is done professionally? The recommended product should be applied to a surface that has previously been cleaned of the remains of old smooth or plaster. The use of Vitcas FRi fireproof plaster is recommended prior to the application of the smoothing coat. The application of the plaster can be carried out on a surface also coated with Vitcas PVA fireproof primer. The recommended maximum thickness of the coating is 3-6 mm and the drying time of the plaster is approximately 3 days at 20ºC.

How do I lay a smooth finish for a satisfying result?

Application of the fire-retardant plaster should be carried out on walls and chimney flues, on walls adjacent to wood-burning cookers and cookers and around fireplaces built into the wall. The drying process of the plaster can be accelerated by additionally heating the room in which it is laid on the walls. If the Vitcas smoothing coat is applied directly onto Vitcas CS fireplace boards or Vitcas HT high-temperature boards, care must be taken to ensure that the surface of the boards is rough. How do I lay the plaster so that it performs its function well? Please note that the plaster must be thoroughly dried and the wall surface treated with a primer. The mass should be applied evenly, in layers. The plaster should not be sanded after it has dried for 3 days.

You may be interested in:

Vitcas oven glue is heat resistant!

Flexible adhesive for induction hobs, high-temperature silicone

When preparing to build a fireplace or cooker, it is good to know how to lay the smoothie so that it is done correctly. You can easily find the right type in the Vitcas shop.